Ever stood bewildered in the ceramics store, staring at clay bodies with cryptic absorption numbers? Wondering what those numbers mean and how they might impact your pottery? Fear not, fellow makers! This blog post is here to demystify the world of clay absorption and empower you to make informed choices for your studio.

What is absorption, and why does it matter?

It all boils down to vitrification. When clay is fired, its minerals melt and fuse to form a glass-like network. This “vitrification” is crucial for strength, durability, and hygiene. The less water a clay absorbs, the more vitrified it is (and the happier your pots will be).

Absorption tells you the amount of water a clay body can soak up. Imagine a thirsty sponge – the more absorbent the clay, the more water it can “drink” in. Thus, the higher the absorption rate (expressed as a percentage), the more water your clay is drinking in. This impacts the clay’s suitability for different uses.

Enroll in CMW Commercial Clay Body Profile Testing for free NOW!

Why 0.5% absorption is the magic number:

Here’s the thing: for functional ceramics (think mugs, plates, bowls), a clay body needs to be vitrified with minimal water absorption. While some clay companies offer bodies with higher absorption rates, we firmly believe that a truly vitrified clay, suitable for functional ware, should have less than 0.5% absorption.

It works like a shield, offering superior strength and resistance to everyday wear and tear. Your dishes won’t just look beautiful, they’ll be built to last. With higher absorption clays, water can seep in, causing cracks and leaks over time, especially during temperature changes.

Enroll in CMW Commercial Clay Body Profile Testing for free NOW!

Testing absorption at home:

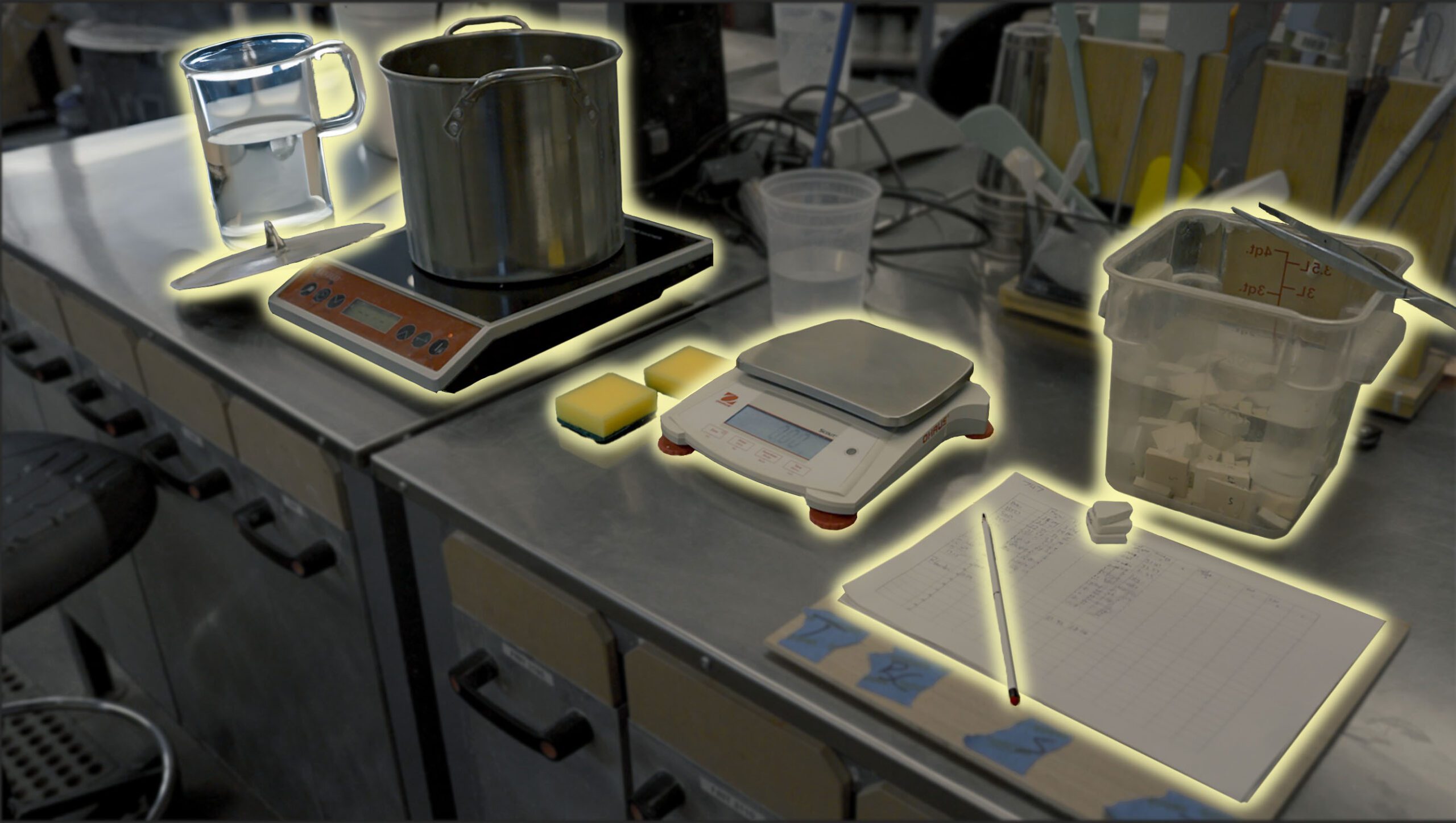

Don’t trust the label blindly- the good news is, you can easily test your clay’s absorption yourself! Here’s what you’ll need:

- Scale: Accurate to 0.01 grams.

- Distilled water: Reduces mineral interference.

- Stove and pot: For boiling.

- Sponge: Damp, not wet.

- Pen and paper: For recording weights.

Follow these simple steps:

- Fire your clay sample unglazed to the highest recommended temperature according to the manufacturer’s instructions.

- Weigh the fired, unglazed sample.

- Boil the sample in water for at least 2 hours (5 hours per ASTM standard for those in industry who are making dinnerware or other commercial products).

- Cool the sample to room temperature.

- Wipe off excess water with the damp sponge (damp is important to note, since a dry sponge could actually absorb some of the water from your sample).

- Weigh the saturated sample.

Interpretation:

- Below 0.5%: Excellent! Your clay is vitrified and safe for functional use.

- 0.5% to 10%: Semi-vitrified. Suitable for some decorative pieces but not recommended for food contact.

- Above 10%: Non-vitrified. Not recommended for functional use due to potential water absorption and bacteria growth.

Now you’re armed with the knowledge to make informed choices about your clay!

But now I want to make a clay body like CMW! Read our article, How CMW makes a plaster slab for testing clay bodies!

Remember, a well-vitrified clay (less than 0.5% absorption) is key for safe and durable functional ceramics.

This blog article is just one of many resources for our community! We’re dedicated to demystifying ceramic materials and processes, equipping you with the knowledge and confidence to create stunning and functional pieces.

One project that we’ve been working on over the past several years is our Commercial Clay Body Profile Testing. Our team has collected and tested scores of commercially available clay bodies to help our students understand how these clay bodies perform to make their studios the best that they can be. Here is a link to view the results of the bodies that have been tested to date. We plan to add additional profiles as we continue to test additional clay bodies.

Enroll in CMW Commercial Clay Body Profile Testing for free NOW!

Need More?

Watch CMW’s YouTube video, Self-Absorbed | How to find your clay body’s absorption Whether you’re a seasoned potter or just starting out, knowing how to interpret these numbers can make a huge difference in your work.

Ready to dive deeper?

Loved learning about ceramic glazes? Want to go even deeper? Check out our Workshops & Courses, now available in Spanish, or YouTube Channel where Matt breaks it all down, myth-busting and Stull chart included!