Ceramic Cone Chart: Kiln Firing Rates

Have you ever glanced at those perplexing columns detailing different firing temperatures for the same cone number and wondered what they truly signify?

If so, you’re not alone. These columns hold vital insights into the delicate balance between firing techniques and the chemical reactions crucial to ceramic artistry.

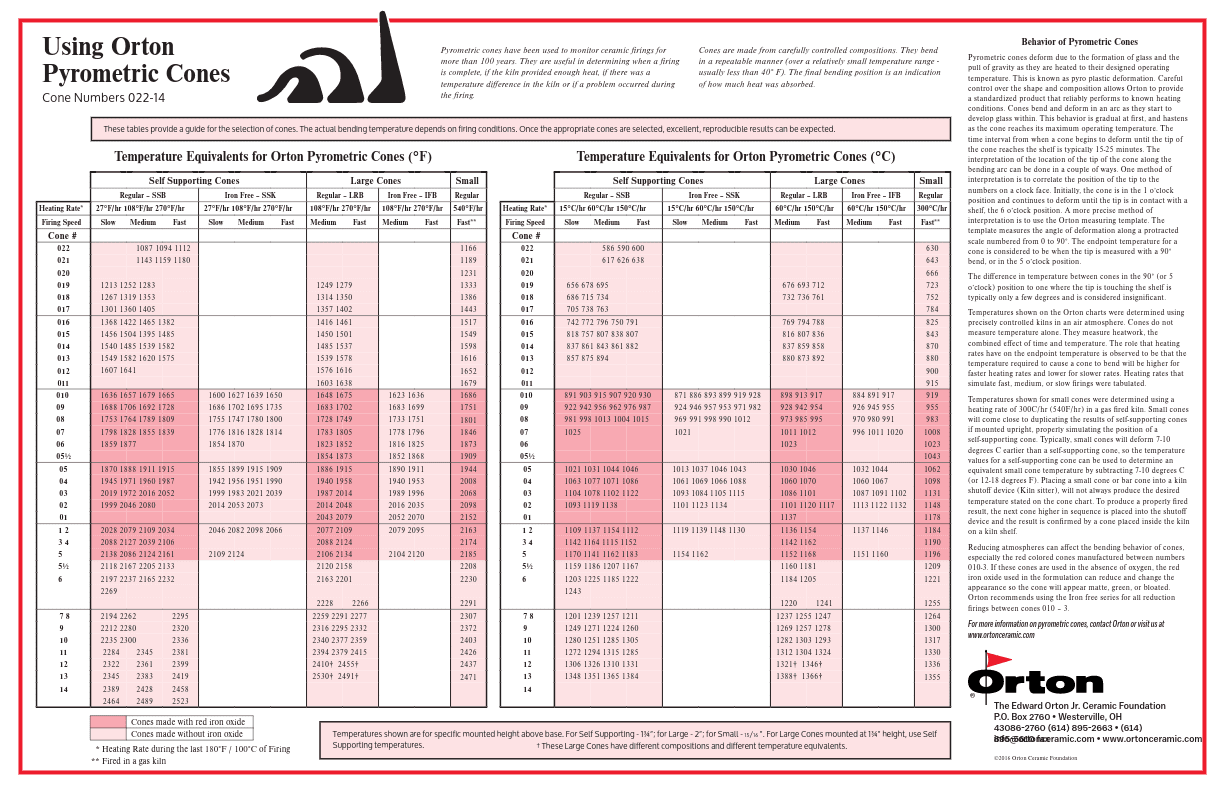

Let’s unravel this mystery together. The column each represent a distinct firing approach—some advocating for a slow and steady ascent, while others champion a rapid rise to the desired temperature. What’s the rationale behind these divergent strategies? (Figure 1)

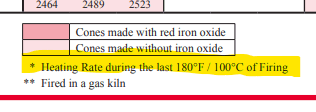

At the heart of the matter lies a profound revelation encapsulated by a seemingly inconspicuous asterisk at the bottom of the columns. This asterisk, my friends, is a game-changer, often overlooked by many. It denotes a critical detail: during the final 180°F/100°C of the firing process, all pertinent chemical reactions unfold. (Figure 2)

Now, let’s dissect this revelation further. Consider the scenario of firing at a leisurely 15 degrees Celsius per hour. On the surface, it appears gentle and methodical, akin to a serene journey through the kiln. However, here’s the catch: while the kiln’s temperature may rise gradually, the extended duration at high temperatures exacts a considerable toll on energy consumption.

Contrast this with a brisk ascent of 60 degrees Celsius per hour—a balance between efficiency and expediency. This firing rate swiftly propels the kiln towards the finish line, minimizing the duration spent at peak temperatures without compromising the integrity of the materials being fired.

But what about the options of 100 and 50 degrees Celsius per hour? At first glance, these rates seem enticing, promising to reach the final 100 degrees in a mere 40 minutes—a seemingly economical choice. However, beware of the potential repercussions. While these rapid firing rates may appear to conserve energy, they run the risk of disrupting the delicate equilibrium of the firing process, potentially jeopardizing the outcome of your creations.

So, where does the solution lie? It lies in finding the elusive sweet spot—the delicate balance between energy efficiency and material integrity. Each firing scenario presents a unique set of considerations, influenced by factors such as the type of clay, glazes used, and desired aesthetic outcomes.

As artisans of the kiln, it’s our responsibility to navigate these complexities with finesse and precision. By carefully calibrating firing rates to suit the specific requirements of each project, we can unlock the full potential of our craft while conserving energy resources.

So let’s heed the wisdom embedded within those enigmatic columns and strive to find the optimal firing rates for our artistic endeavors. For in the realm of ceramics, as in life, balance is key—a delicate dance between efficiency and artistry, culminating in masterpieces forged in the fires of creativity.

With this knowledge and testing, you can make informed choices about your kiln firings to make your studio and work the best that it can be. But this is just the beginning!

Have a few minutes? Check out our Ceramic Cone Shorts on our YouTube channel here. Make sure that you subscribe to be notified when we add new content.

If you haven’t already, join our community. Learn more by exploring our online courses and workshops, follow us on Social Media @ceramicmaterialsworkshop or sign up for our Newsletter.

Together, we can build a community of informed and empowered ceramic makers who value quality and craftsmanship.

-The CMW Team