The CMW team recently had the opportunity to visit Fiesta Tableware in Newell, WV. It was a thrill, as we always love visiting factories and seeing how they produce their ceramics. It is amazing that the way they work with clay is the same way the artist community does. They just think about it in a different way.

The first thing for making great pots is making great clay! In industry they mix clay differently than artists clay (and the artists clay manufacturers should step up their game!) Shown in the images below, Fiesta uses a filter press, where the clay is mixed as a slip with a lot of water (first picture on left), then the filter press is used to squeeze all the extra water out. That leaves the cakes you can see in the second picture. Those go through a wad mill (third picture) which chops up the clay and evens the moisture content. Then into the pug mill for de-airing (fourth picture). Then loaded onto carts and taken to production! (last picture)

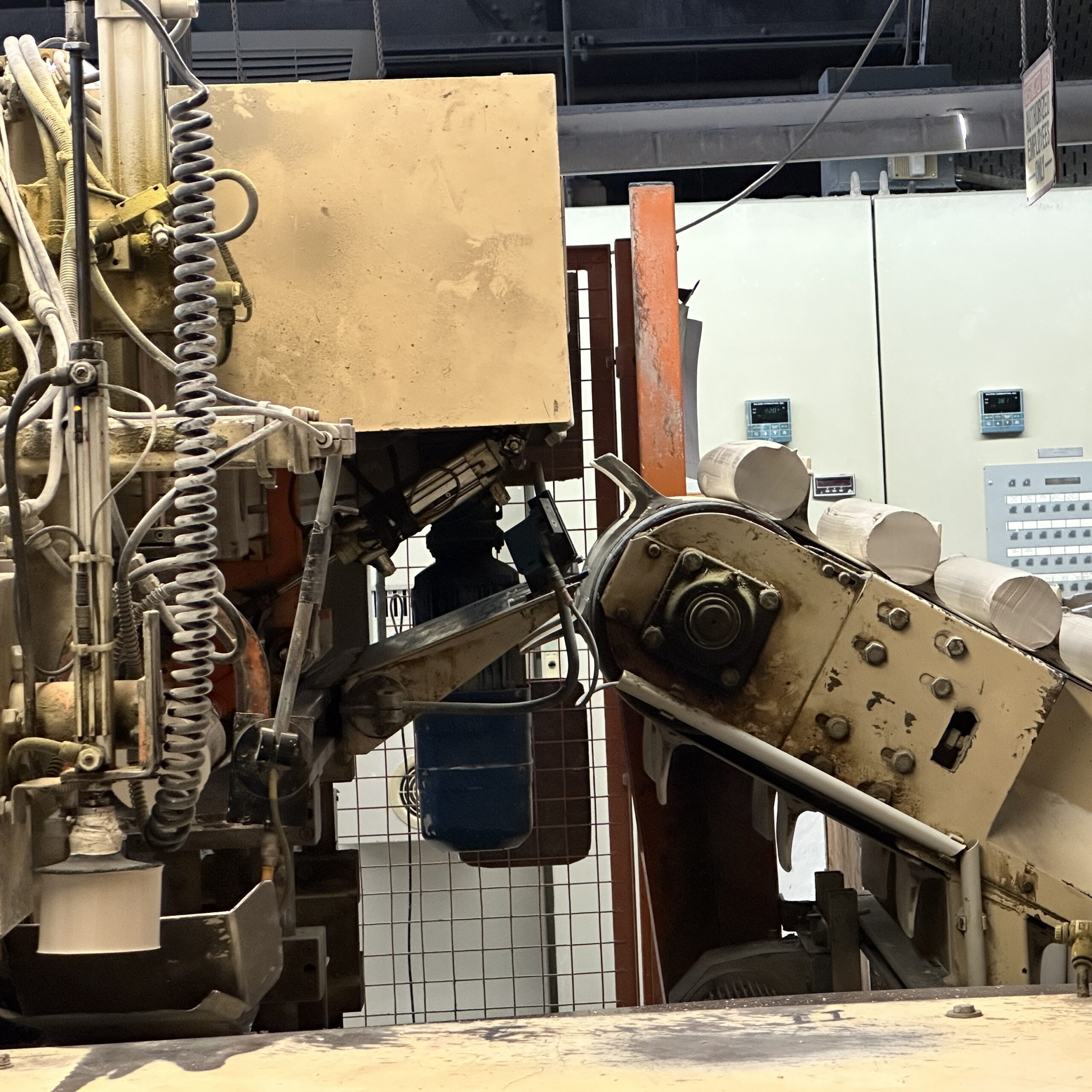

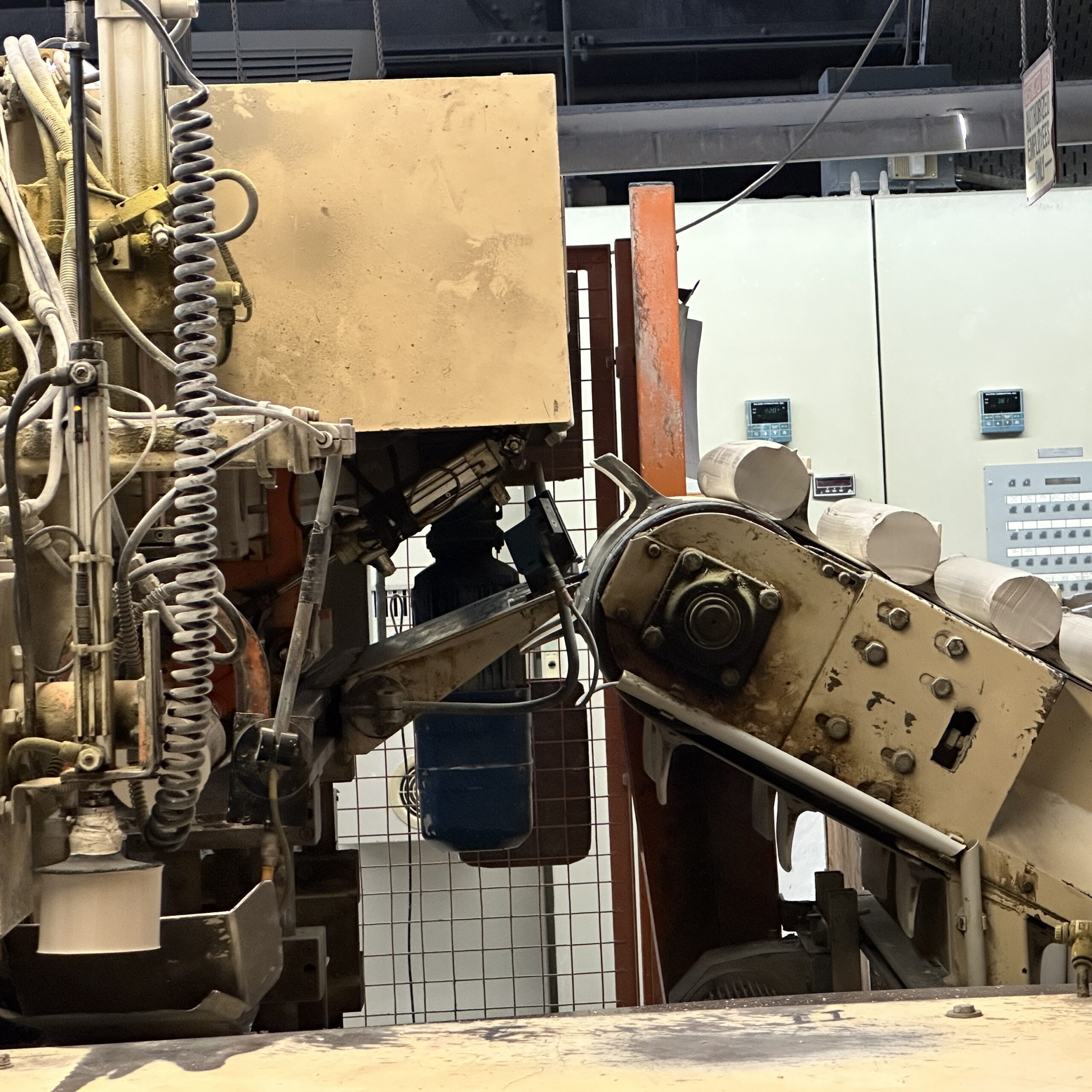

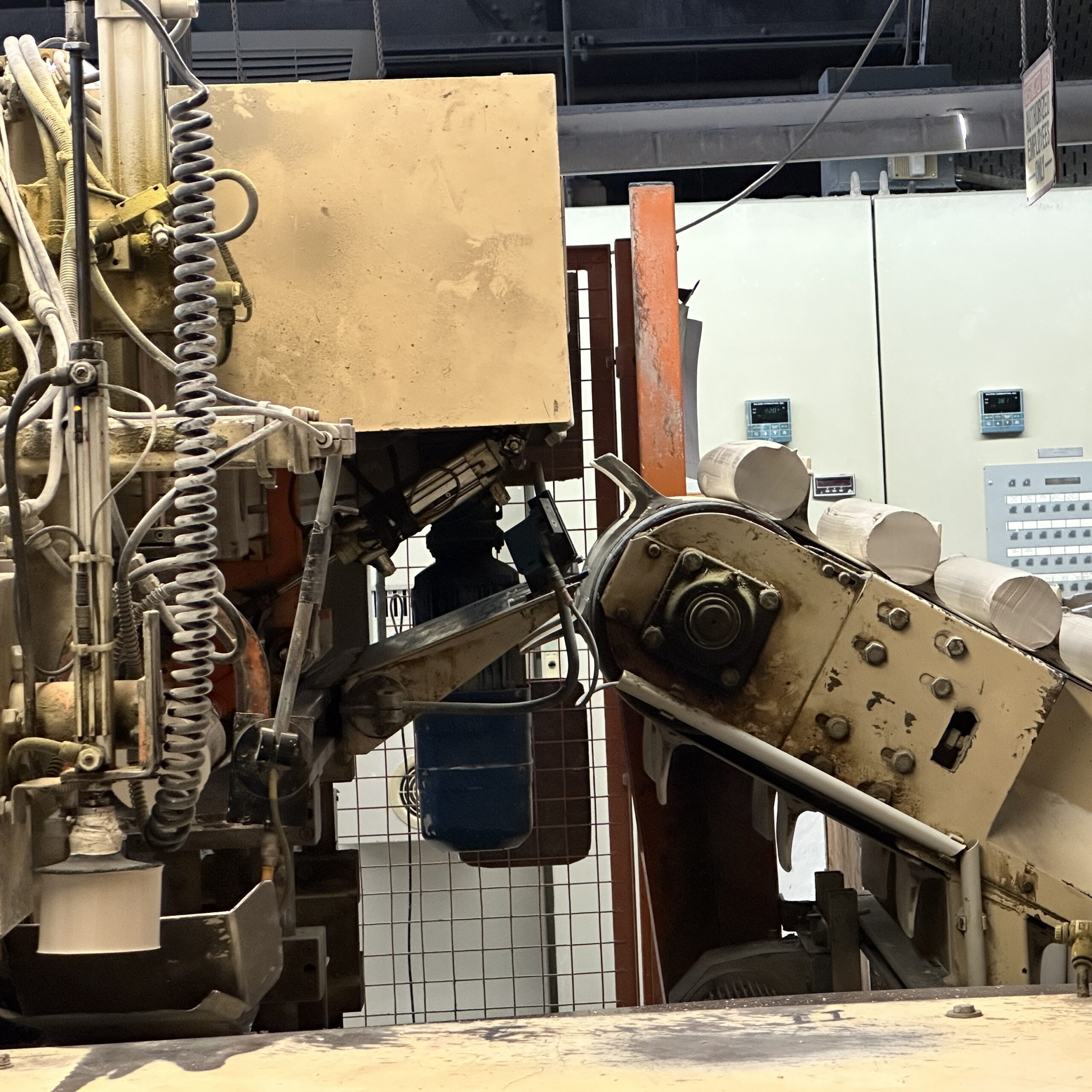

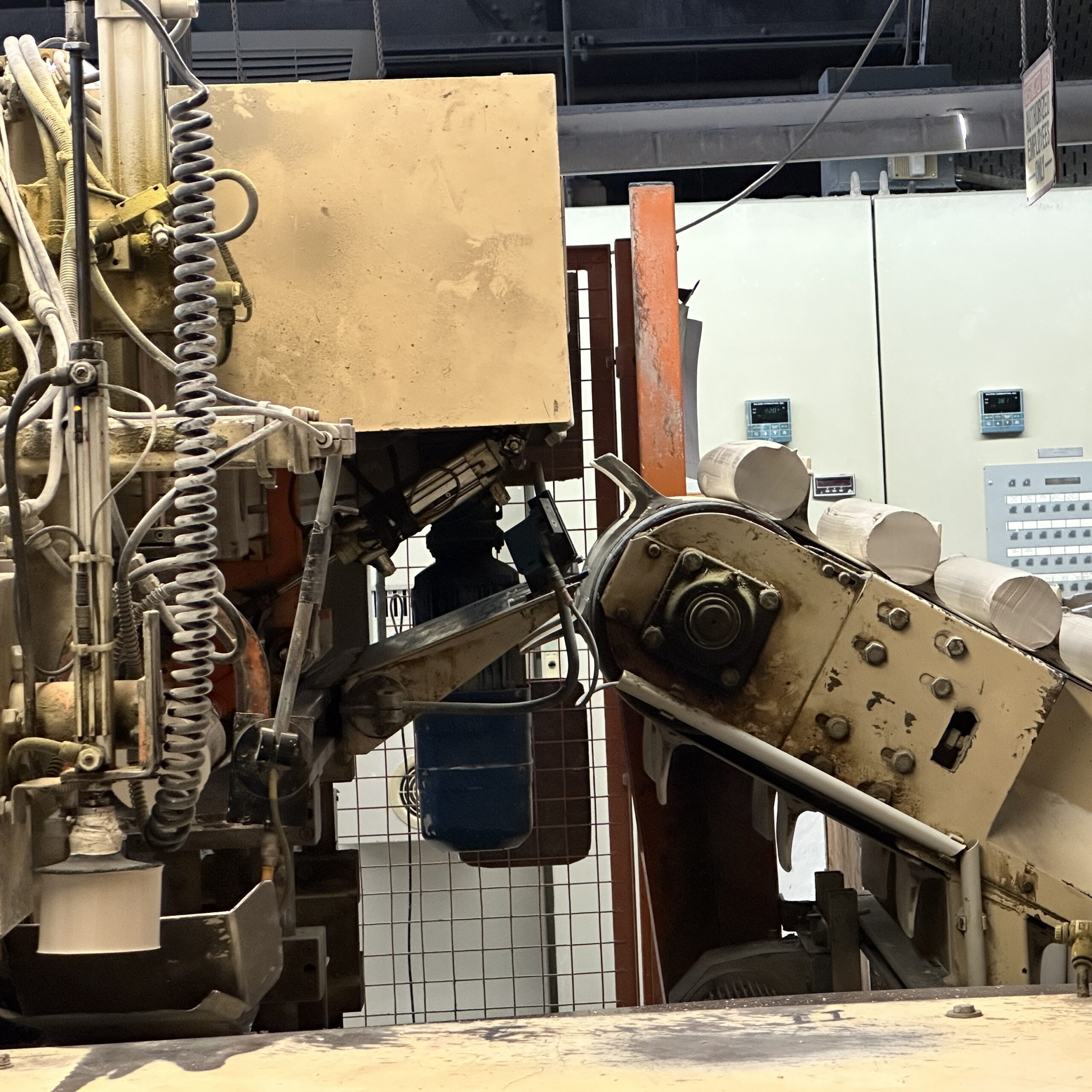

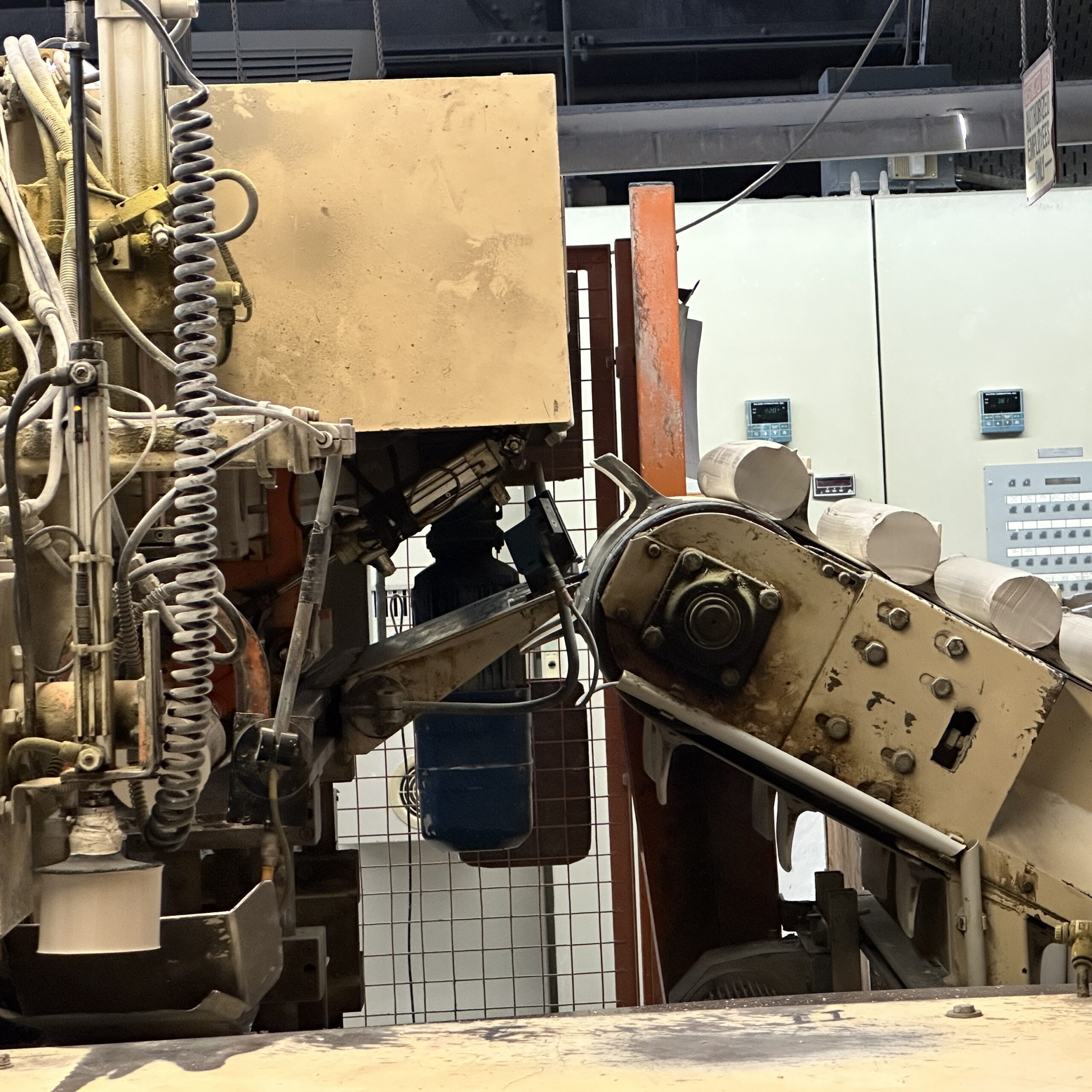

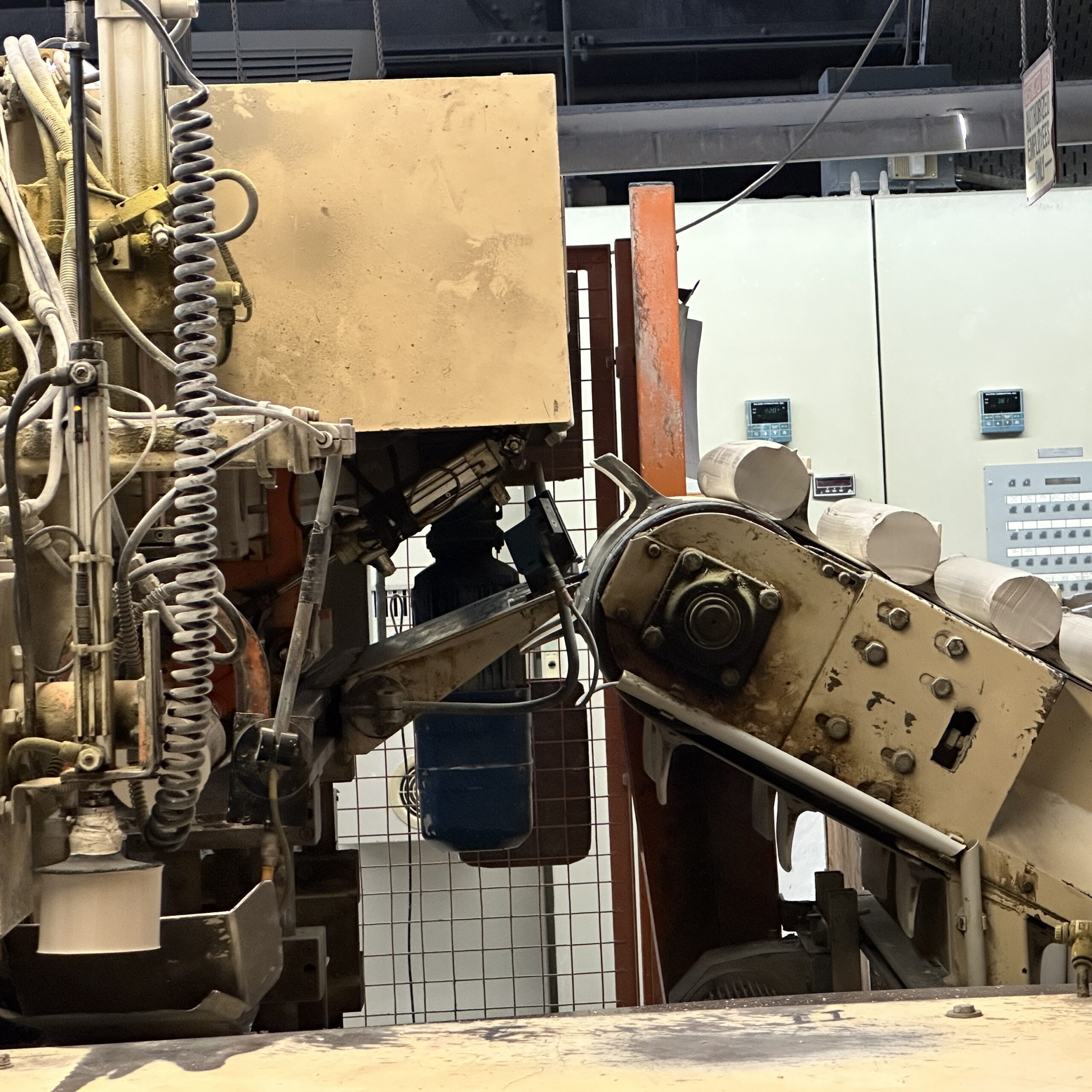

Fiesta Dinnerware makes pots through lots of different methods. The way shown in the images below uses a Jigger, which is the industrial version of a wheel. The clay is pressed into a spinning wheel (first picture on left) and then the clay slugs from the filter press are fed into the line (middle picture), sliced to be the right amount, then pressed (last picture). This line makes two different shapes at once.