This is precisely why glaze testing isn’t just an optional step; it’s a fundamental pillar of successful ceramic practice.

Still not convinced? Let’s dive into the critical reasons why every potter, from beginner to professional, should embrace the humble glaze test tile.

The Ultimate Fit Test: Glaze & Clay Body Harmony

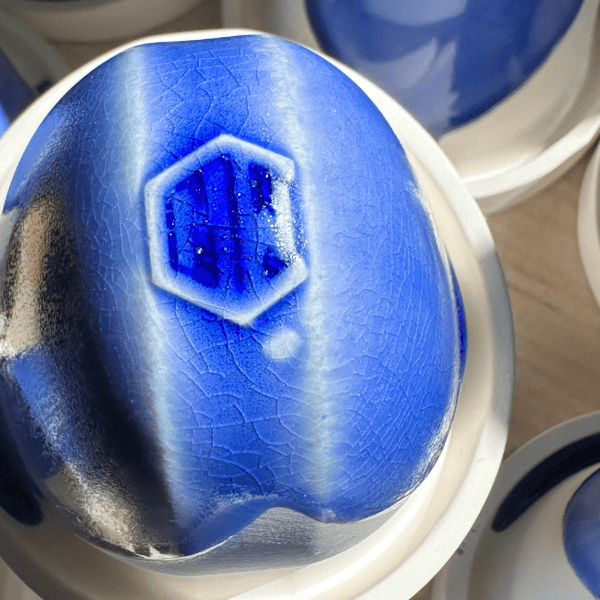

- Crazing: Those fine, web-like cracks in the glaze that might look artistic, but often indicate a poor fit. For functional ware, crazing creates microscopic highways for bacteria, making the piece unsanitary.

- Shivering: The opposite of crazing, where the glaze literally flakes or peels off the clay. This is a significant safety hazard, especially on dinnerware.

- Dunting: The most dramatic, and heartbreaking, failure. Your pot cracks or even explodes, sometimes hours or days after cooling, due to severe thermal stress.

The Unseen Threat: Food Safety & Chemical Leaching

Beyond aesthetics, the health and safety of your ware are paramount, especially for pieces intended for food or drink. Some glaze ingredients, particularly certain metal oxides used for vibrant colors, can leach harmful chemicals into food if the glaze isn’t stable or properly fired.

- The Acid Test: To determine lead levels, ceramics are soaked in a 4% acetic acid solution for 24 hours, simulating the acidic conditions of food and beverages.

- Lab Analysis: The solution is then analyzed to measure the amount of lead released.

- Allowable Limits: The FDA sets different limits for different types of dinnerware:

- Flatware (plates, bowls): 3 milligrams of lead per liter.

- Cups, mugs, pitchers: 0.5 milligrams of lead per liter.

Glaze testing provides peace of mind, ensuring your pieces are safe for their intended use.

But what about lead!? Do not be afraid! CMW breaks it down in our blog: The Truth About Lead in Ceramics

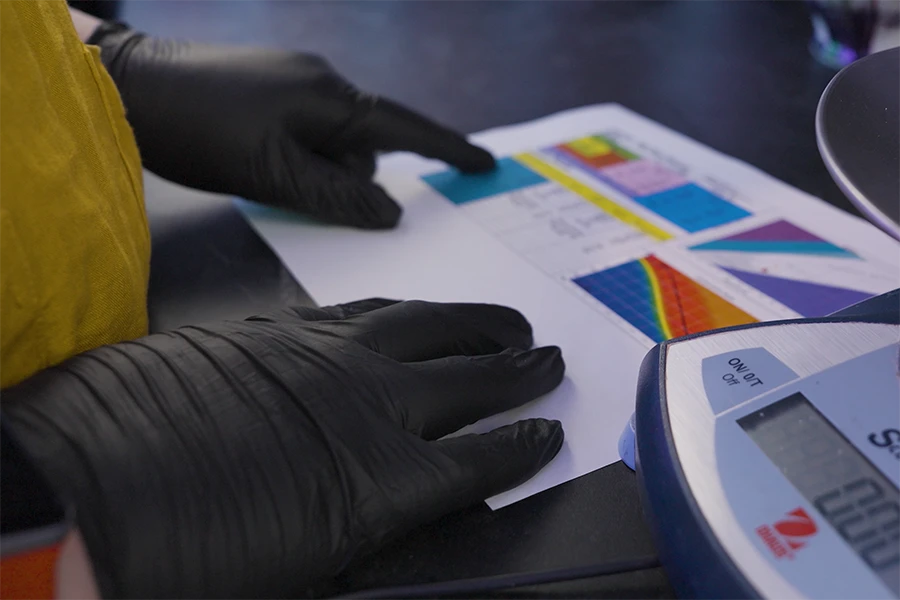

Predicting the Magic: Color, Texture & Application Surprises

- Witness True Color: See the actual hue, transparency, and opacity of a glaze on your specific clay body, under your specific firing schedule.

- Explore Texture: Determine if the glaze will be glossy, matte, satin, speckled, or something entirely unique.

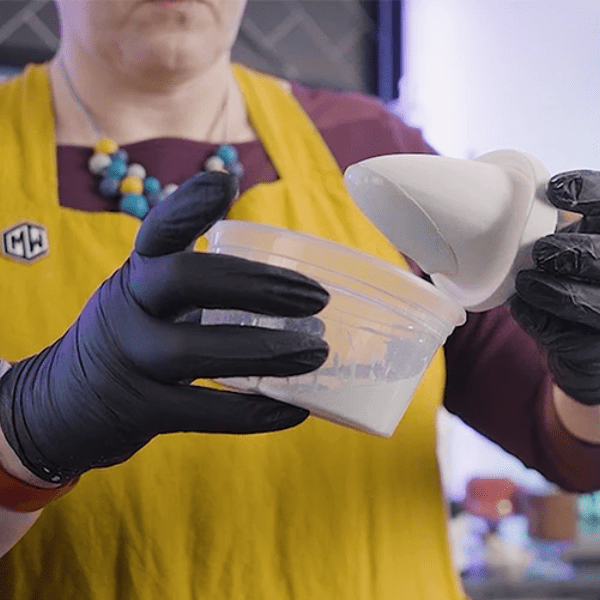

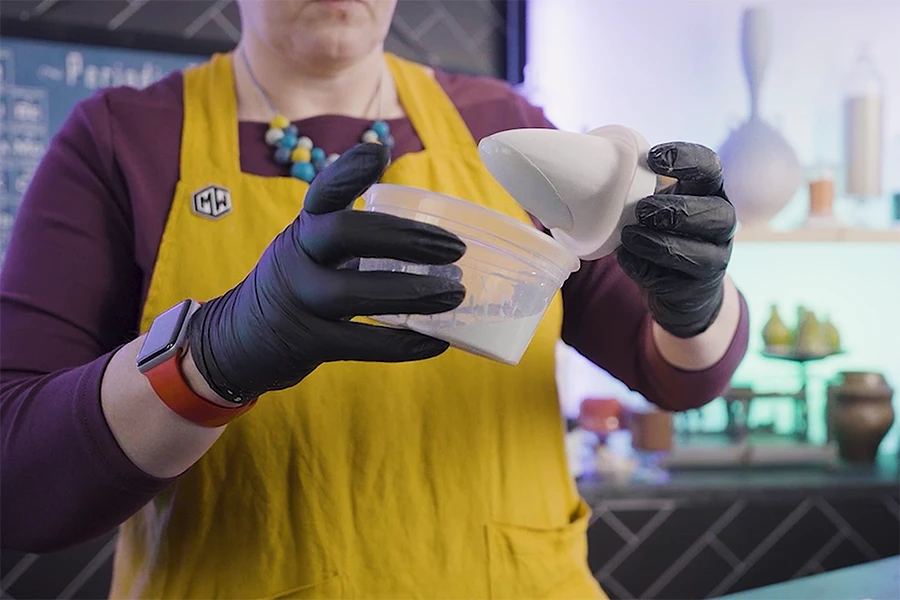

- Master Application: Understand how different methods (dipping, brushing, spraying), varying thicknesses, and layering affect the final look.

- Decipher Interactions: Discover how your glaze reacts with underglazes, oxides, or other glazes.

Testing demystifies the kiln, allowing you to achieve consistent, predictable, and beautiful results.

Decoding Glaze Behavior: From Flow to Flaws

Glazes are complex chemical concoctions. Testing helps you become a glaze detective, observing their behavior in the kiln:

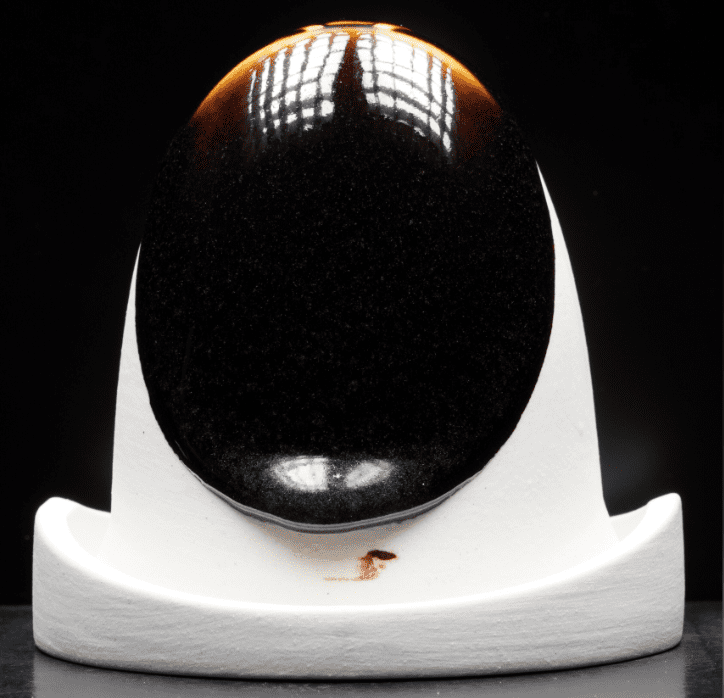

- Melt Fluidity: Does the glaze run excessively, or does it stay put?

- Crystallization & Clarity: Does it form interesting crystals, or remain a clear, glassy surface?

- Identify Defects: Catch issues like crawling (glaze pulling away from the clay), pinholes, bubbling, or blistering before they ruin a finished piece.

Saving Time, Money & Heartbreak

Imagine spending hours on a detailed sculpture, only for an untested glaze to ruin it. Glaze testing, while seemingly an extra step, is a massive time and cost saver in the long run.

- Preventing Ruined Pieces: Small test tiles are cheap and quick to make. Sacrificing a few tiles is far better than losing a large, intricate pot.

- Efficient Recipe Refinement: If you’re mixing your own glazes, testing allows you to systematically adjust recipes to achieve desired effects, minimizing material waste.

Invest a little time in testing now, and save yourself a lot of frustration (and money) later.

Building Your Knowledge Base: The Power of Documentation

Perhaps the most valuable outcome of consistent glaze testing is the creation of a personal glaze library.

- Record Everything: Note the glaze recipe, the clay body used, your exact firing schedule (cone, ramp rates, hold times), application method (how many coats, brushed/dipped), and the results (with photos!).

- Learn and Grow: This documentation becomes an invaluable resource for troubleshooting, replicating successful outcomes, and inspiring new glaze developments.

Every test is a learning opportunity, refining your skills and expanding your ceramic vocabulary.

So, next time you’re tempted to just slather on that new glaze recipe, remember the humble test tile. It’s your window into the future of your pottery, transforming uncertainty into confidence and ensuring your ceramic creations are not just beautiful, but also durable, functional, and safe. Happy testing!

Test test test…AND MORE TESTING!

Ceramic Materials Workshop is a place online to understand and explore how and why our Clay and Glazes work (and don’t work). Our materials speak for us in the home and gallery. It benefits us to learn about how to speak through our materials. Mastering the skills of clay and glaze performance helps every ceramicist, become their best self in the studio.

Ready to dive deeper?

Loved learning about ceramic glazes? Want to go even deeper? Check out our Workshops & Courses, now available in Spanish, or YouTube Channel where Matt breaks it all down, myth-busting and Stull chart included!