Reduction is a new concept for a lot of people, that’s because the majority of people are firing in electric kilns, which basically only fire in Oxidation (there are some ways to do it, but they aren’t the safest or most stable).

The Heat is ON! A Beginners Guide to Glazing & Firing Pottery

Most people think about Reduction in reference to copper reds, which we have been talking about recently. But there are a few materials which also can be changed by reduction, and one of those is simple, unassuming Tin Oxide (SnO2).

Tin is considered an opacifier, which we use to make glazes white. It used to be used a lot more, but now it is very expensive and Zirconium Silicate opacifies for a cheaper cost.

But Tin still has a place in glazes like Copper Reds and Chrome Tin pinks, that we were discussing a few weeks ago.

But Tin is important to understand, because in reduction it changes from SnO2 to SnO, which changes the way it interacts with the glaze.

Here we have one glaze, all four tests are from the same batch. We mixed it and dipped two test tiles, then added 5% Tin and dipped two more. We then fired one of each in a oxidation firing and one of each in reduction. You can see that only one of the glaze (upper right) is white (opacified) the others are all clear.

That is because those glazes either didn’t have Tin at all (bottom row) or the Tin was reduced(upper left), changing its properties and removing its opacifying abilities.

Did you know you can make glazes using pyrometric cones? Read more in CMW’s article: Cone-ception: The Unexpected Use of Pyrometric Cones

Copper Red glazes are interesting as they often contain a lot more Tin than Copper. We’ve seen formula that will have 0.5% Copper and 6x or more Tin.

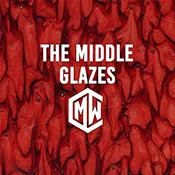

These two glazes are from the same batch. The tile on the right is without Tin. We then added the Tin, and applied a second tile, which is on the left. Both were then fired in the same reduction firing.

Why?

Well, the copper makes the red, Copper is reduced down to colloidal copper (ultra small) this looks when suspended in a glass. That much is clear.

One theory on why the tin is included is that it opacifies the glaze, which makes the red more intense. That doesn’t quite work conceptually, as opacifiers tend to change the colors they are mixed with, into pastel colors.

One theory pro-ported by Tschane, in his book copper red glazes, is that it is the reduced behavior of tin that enables the red. Most materials, when reduced, want to reoxidize while still in the firing. The idea is that Tin will reoxidize before cooper, and in that process strips all of the remaining oxygen from the copper, giving it an even more bold color. This behavior is also why the “oxidation flash” in copper red firings is valuable.

Our student Mel @a_fizzy_dilu on instagram, has found some studies that validate this concept.

These are the same glaze, again made without Tin on the right, adding Tin to the same batch on the left. This time, the glaze is just increasing the level of opacity.

As we said in earlier post today, when we opacify a glaze, aside from making it white, it tends to make glazes “pastel” which is color theory terms, meant to mix a glaze with white. Which lightens the overall appearance.

One thing to mention…We are hearing through the grape vine, that Tin prices are about to skyrocket. So if you use a lot of Tin on your work, it may be time to invest.

Ready to dive deeper?

Loved learning about ceramic glazes? Want to go even deeper? Check out our Workshops & Courses, now available in Spanish, or YouTube Channel where Matt breaks it all down, myth-busting and Stull chart included!