We’re absolutely buzzing with excitement to share some fantastic news! The team here at Ceramic Materials Workshop recently had the pleasure of partnering with the brilliant folks over at Hammerly Ceramics, and let’s just say, sparks flew (the good, non-kiln-malfunction kind!).

Who is Hammerly Ceramics? They make one of a kind hand made porcelain mugs & ceramic art in Colorado! See More from them HERE!

Hammerly Ceramics, known for their stunning and high-quality ceramic creations, came to us with a challenge we were thrilled to tackle. They were looking to level up their production by moving away from relying on pre-made slip materials that, let’s be honest, can sometimes be a bit of a wild card in terms of consistency.

Their mission? To nail down a Cone 10 porcelain casting slip formula that was not only optimized for super-speedy casting times but also delivered top-notch fired performance. And guess what?

We were ready to roll up our sleeves and dive deep into the world of clay science to make it happen!

Why go custom?

Well, as any ceramic artist knows, consistency is king (or queen!). By crafting a bespoke, in-house slip formula for Hammerly, we’re empowering them to:

- Say goodbye to batch-to-batch variations! Imagine the peace of mind knowing your materials are performing exactly as expected, every single time.

- Unlock significant cost savings! Streamlining their material sourcing and production can have a real impact on the bottom line.

- Fine-tune their process for ultimate efficiency! A slip designed specifically for their needs means optimized casting times and potentially higher throughput.

What’s the roadmap for a project like this?

Typically, a deep dive into creating a custom slip formula and getting it dialed in for production takes around three to six months. This allows us the time to meticulously develop, test, and refine the formula to ensure it hits all the right notes for Hammerly’s specific needs.

Our secret sauce?

Consistency, consistency, consistency! Once we’ve landed on that perfect slip formula, our approach is all about making sure it stays perfect. We’ll be working with Hammerly to establish clear targets for key performance indicators – think casting behavior and the final fired clay.

Regular testing will be the name of the game, allowing us to track any subtle shifts from batch to batch and over time. This data-driven approach means we can make informed, measured adjustments, keeping that slip performing like a dream.

Why Us?

With years of hands-on experience troubleshooting all sorts of slip-related gremlins (from greenware defects to raw material hiccups), our team is well-equipped to anticipate and address any potential challenges.

We’ve seen it all in the casting shop and the slip and glaze department, and we’re passionate about finding practical, effective solutions.

What makes a fantastic in-house slip?

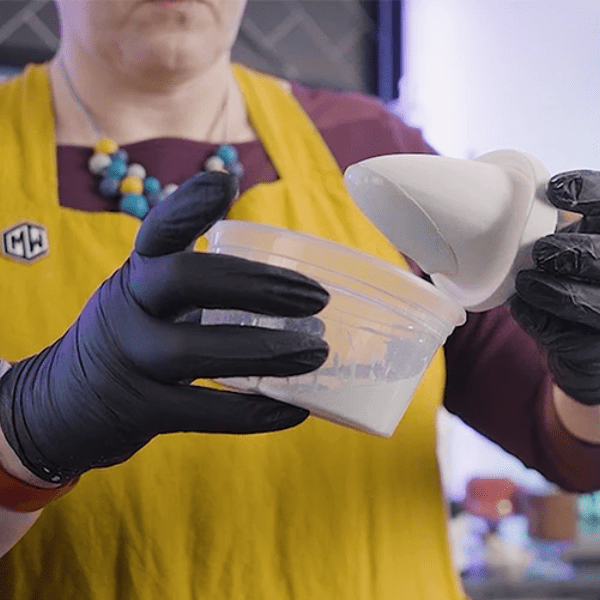

For us, it’s all about repeatability. While maker preference plays a role, we generally aim for a specific gravity above 1.7 for optimized casting speed and gel times that are longer than the casting time to ensure a flawless cast.

“Will I Receive a Full Report?”

And yes, Hammerly will be receiving the full scoop! We’re putting together a detailed written report outlining the magic formula, step-by-step mixing instructions, and our recommended testing procedures. Knowledge is power, and we want to equip Hammerly with everything they need for long-term success.

How do you adapt to the ever changing world of ceramics?

Staying ahead of the curve in the world of ceramic materials is a constant journey. While the core of traditional ceramics is an ancient art, we keep our eyes peeled for those smaller, but significant, improvements and variations in the industry. Sometimes, a trip down the dinnerware aisle can spark unexpected insights! We also stay connected with clay makers and material suppliers to stay informed about any upcoming changes in the market.

We’re incredibly excited about this collaboration with Hammerly Ceramics and are confident that this custom slip solution will be a game-changer for their production.

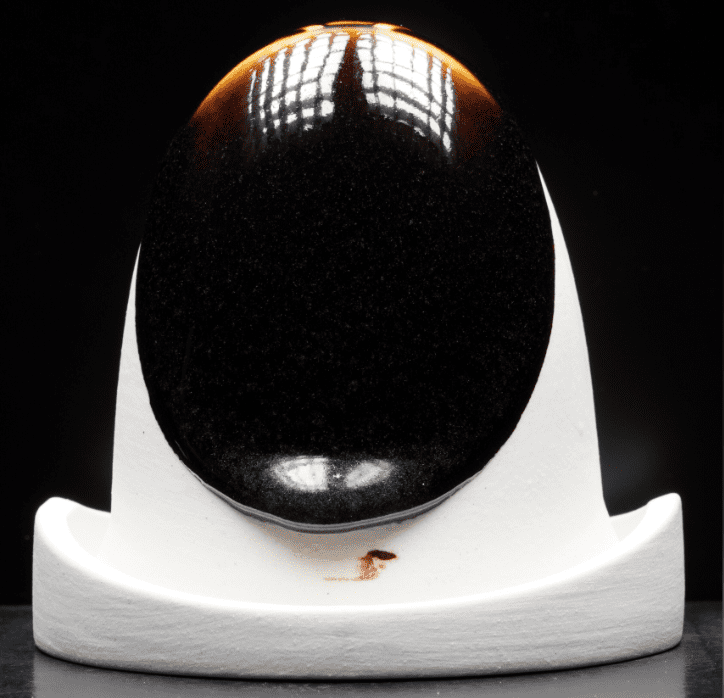

Who is Hammerly Ceramics? They make one of a kind hand made porcelain mugs & ceramic art in Colorado! Below is some of there work to See more from them CLICK HERE!

Interested in CMW’s Consulting?

Rose highlights common issues like glaze failures and inconsistent clay results, offering customized consulting services. The CMW team specializes in diagnosing flaws and optimizing materials for growth. They also provide community resources, including a used equipment database and training programs, to strengthen the ceramic industry through collaboration.

Ready to dive deeper?

Loved learning about ceramic glazes? Want to go even deeper? Check out our Workshops & Courses, now available in Spanish, or YouTube Channel where Matt breaks it all down, myth-busting and Stull chart included!