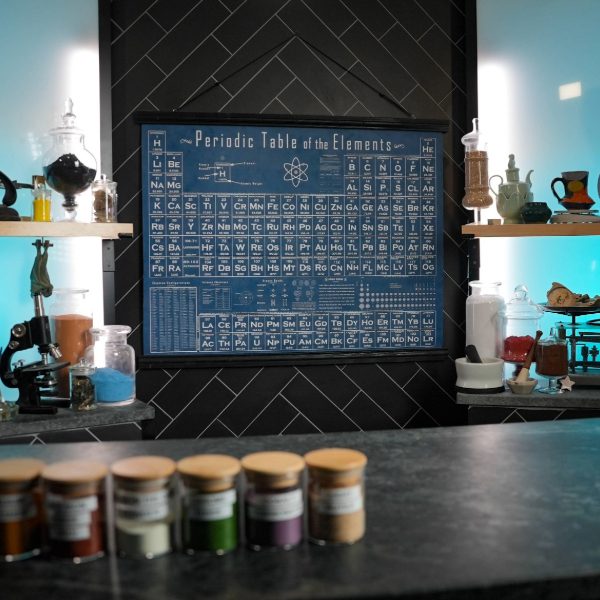

This is our glossary to help provide a foundation for beginners looking to understand glaze and clay chemistry terms. By familiarizing yourself with these terms, you can navigate the world of pottery with greater confidence.

Glaze Chemistry Terms

- Batch: A mixture of raw materials in specific proportions, prepared for a glaze recipe or clay body

- Bisque: Clay that has undergone the first firing to bisque temperatures

- Brushing: Applying glaze with a brush. (Explain more here…)

- Celadon: A Chinese glaze known for its jade-green color.

- Crystalline: Glazes that develop visible crystals during firing.

- Dipping: Applying a glaze by Immersing the pottery in a bucket of glaze.

- Fit: The ability of a glaze to match the expansion and contraction of the clay body.

- Flux: A material that lowers the melting point of a glaze.

- Glaze: A glassy coating applied to pottery to add color, texture, and durability.

- Glaze Flaw: Any unintended defect or imperfection that appears in the glaze after firing

- Glass Former: The primary component that forms the glassy matrix.

- Glossy: Glazes that reflect light in a mirror-like way, creating a shiny, smooth surface

- High-fire: Glazes fired at cone 6 or higher.

- Low-fire: Glazes fired at cone 06 or lower.

- Map (Stull’s map): A graphical tool used in ceramics to predict the behavior of glazes based on their chemical composition

- Matte: Glazes with a dull, non-reflective finish.

- Maturity: The degree to which a glaze has melted and vitrified.

- Opacifier: A material that makes a glaze opaque.

- Oxidation: The chemical process where a glaze reacts with oxygen during firing.

- Oxide: A compound made of oxygen and another element (like iron oxide, copper oxide). In glazes, oxides provide color and can affect melting behavior.

- Pouring: Applying a glaze by pouring glaze onto the pottery.

- Raku: A low-fire glaze removed from the kiln hot and cooled rapidly.

- Reduction: Refers to the chemical process where a glaze reacts with a reducing atmosphere during firing.

- Salt Glaze: A glaze formed by introducing salt vapor into the kiln.

- Shino: A Japanese glaze with an iron-rich composition and matte finish. (Learn more…)

- Silica to Alumina Ratio: The ratio of silica to alumina, which affects glaze properties.

- Spraying: Applying glaze with a spray gun.

- Test tile: A small piece of clay used to test glaze formulas and firing conditions (Try out CMW’s now!)

- Thermal Expansion: The rate at which a glaze expands or contracts with temperature changes.

- Underfired: Clay or glaze that has not been fired to a high enough temperature in a kiln

- Viscosity: The resistance of a glaze to flow.

- Vitrification: The process of a glaze melting and becoming glassy.

- Woodfire Glaze: A glaze developed in a wood-fired kiln

Master ceramics terminology Ceramics Terms (downloadable flashcards)

✨ Unleash your inner ceramic artist with Glaze of Our Lives! ✨ This beginner-friendly course, led by expert Matthew Katz, empowers you to create stunning ceramic pieces. Watch a FREE sample lesson on our YouTube channel and start your creative journey today!

Ready to dive deeper?

Loved learning about ceramic glazes? Want to go even deeper? Check out our Workshops & Courses, now available in Spanish, or YouTube Channel where Matt breaks it all down, myth-busting and Stull chart included!