Ever dreamed of creating stunning pottery without the need for a high-fire kiln? Bristol glazes are your answer! These glazes can transform your clay creations into works of art at lower temperatures, making them accessible to ceramics of all levels.

In this guide, we’ll delve into the world of Bristol glazes, exploring their unique properties, benefits, and applications.

What are Bristol Glazes?

Bristol glazes are a special type of glaze that can be fired at lower temperatures, typically around cone 6, (The superior cone) compared to traditional glazes that require higher temperatures (cone 10). They achieve this remarkable feat through a unique chemical reaction involving zinc and calcium.

How They Work

Unlike traditional glazes that rely on fluxes like sodium or potassium to lower the melting point of silica and alumina (the main components of glass), Bristol glazes harness the power of zinc and calcium. (Show me a cone chart!) This combination creates a “eutectic reaction,” where the mixture melts at a lower temperature than either zinc or calcium alone. This allows potters to achieve a beautiful, glossy glaze without the need for high-fire equipment.

Advantages of Bristol Glazes

- Lower Firing Temperatures: This makes them ideal for potters with limited kiln access or those who prefer working with clay bodies that mature at lower temperatures.

- Cost-Effectiveness: Bristol glazes are often more affordable than traditional glazes that require boron or other expensive fluxes. (More budget friendly glazes here!)

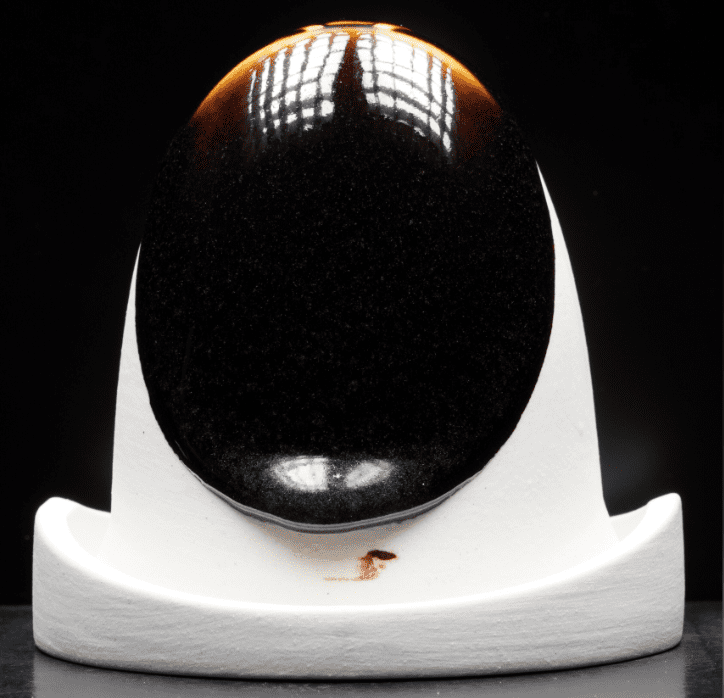

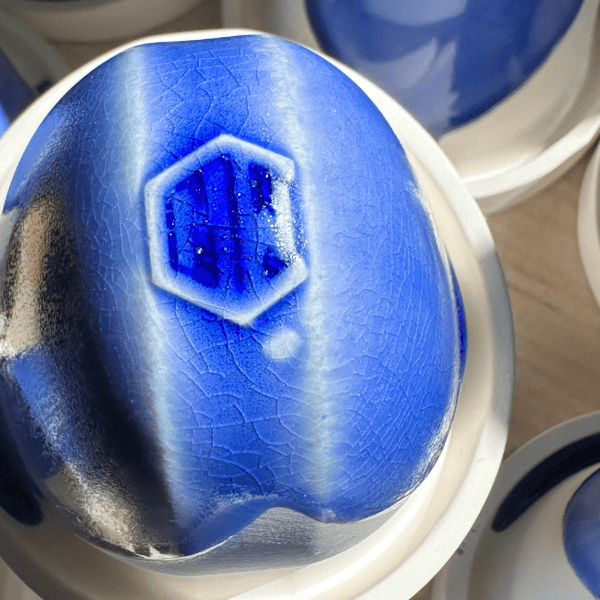

- Versatile Effects: Bristol glazes can produce a range of stunning effects, including matte, glossy, crystalline, and phase separation.

How can I get the best firing out of my kiln? Find out more in our podcast For Flux Sake, Episode 91

Limitations of Bristol Glazes

- Less Vibrant Colors: Some colors, particularly those containing copper, may be slightly less vibrant compared to glazes with other fluxes.

- Durability: Some Bristol glazes, especially those containing copper, may have reduced durability when exposed to acidic substances.

Sample Formula of a Bristol Glaze

- Cone 6 Bristol Glaze Example:

- Nepheline Syenite 39.49%

Whiting/ calcium carbonate 16.01%

Whiting/ calcium carbonate 16.01%- Zinc oxide 10.67%

- EPK or kaolin 7.47%

- Flint/ silica/ quartz 19.81%

- Cobalt carbonate 0.93%

- Titanium dioxide 5.61%

- Water 80%

Bristol glazes offer a valuable alternative for potters seeking lower firing temperatures. While they may have slightly muted colors, their functionality and affordability make them a popular choice. Help me understand the cones more!

Okay…I get it! What’s so special about a Bristol Glaze though? Listen to CMW’s podcast, For Flux Sake, Episode 78.

In Conclusion

Bristol glazes offer potters a versatile and affordable option for creating stunning, low-fired ceramics. Whether you’re a beginner or a seasoned potter, experimenting with Bristol glazes can open up a world of creative possibilities. So, why not give them a try and discover the magic of Bristol glazes for yourself?

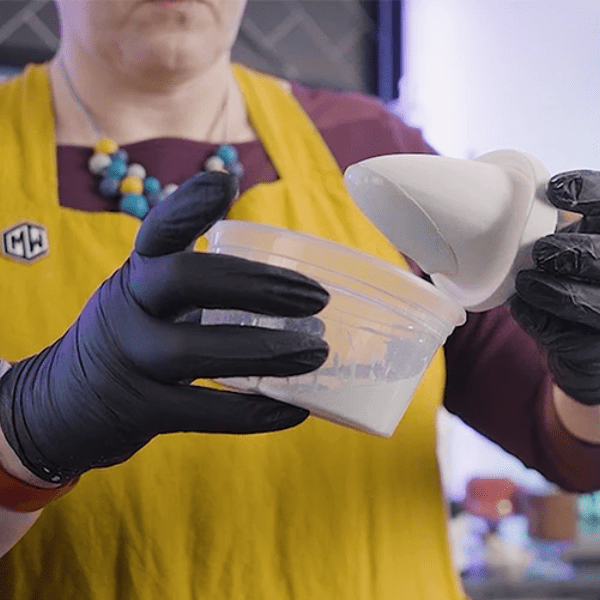

Remember: Always test your glazes on test tiles before applying them to your final pieces, as results can vary depending on clay body and firing conditions.

Did you know you can make your own glaze? 5 Reasons you Should Make your own Glaze!

Still Curious?

You can learn more about Bristol Glazes on our YouTube channel. Matt breaks down the Bristol glaze reaction that fires perfectly at cone 6—and shares it with you in our Cracking the Kiln segment – How do Bristol Glazes work?

Ready to dive deeper?

Loved learning about ceramic glazes? Want to go even deeper? Check out our Workshops & Courses, now available in Spanish, or YouTube Channel where Matt breaks it all down, myth-busting and Stull chart included!