First things first, let’s put your mind at ease.

Handmade and small-batch functional ceramics made in the United States do not use lead in their production.

This practice has been in place for decades, ensuring that your handcrafted mugs, bowls, and plates are lead-free and safe for everyday use.

Even major dinnerware companies in the US, like Fiestaware, stopped using lead in their products way back in 1986. So, if you’re buying new ceramics from reputable sources in the US, you can be confident that lead isn’t an issue.

We even visited Fiesta Dinnerware factory in Newell, WV! Read more here!

Here at Ceramic Materials Workshop, we’re all about science and safety. And the truth is, lead itself isn’t the issue. It’s all about how it’s used and, most importantly, how much actually leaches out into your food or drink.

Mythbusters: Debunking the Lead Scare

Let’s start by addressing a common misconception:

- Myth: All ceramic glazes, especially handmade ones, contain dangerous levels of lead.

- Fact: Handmade and small-batch functional ceramics produced in the United States have largely eliminated lead from their production processes. This has been the standard for decades, ensuring safer pottery for everyday use.

- Fact: Even major dinnerware companies in the US, like Fiestaware, stopped using lead in their products as far back as 1986.

Understanding the Real Risks

While lead has caused significant problems in other industries (like paint, gasoline, and plumbing), its presence in modern ceramics is tightly regulated. It’s crucial to understand that:

- Social media sensationalism often exaggerates the risks.

- Lead is naturally present in the environment; trace amounts can be detected even with rigorous testing.

The Historical Role of Lead in Glazes

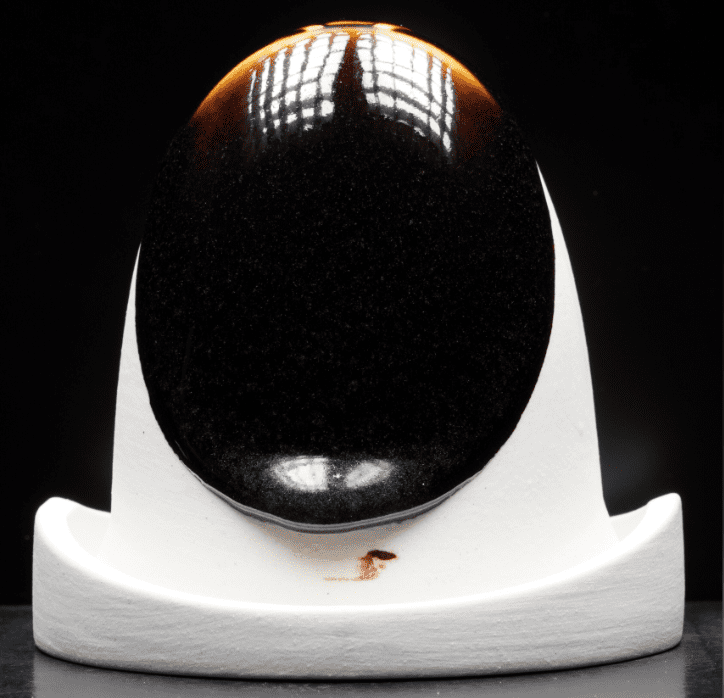

Historically, lead was used as a flux in ceramic glazes, lowering the melting point of silica (the primary component of glass). However:

- Lead constituted only a small percentage of the glaze composition, even in older formulations.

- A glaze’s transparency doesn’t indicate the presence or absence of lead. All glazes are inherently clear; the clay body determines opacity.

The 24-Hour Soak Down: The Science Behind Safety

To accurately determine lead levels, a rigorous testing procedure is employed:

- The “acid test” involves soaking ceramics in a 4% acetic acid solution for 24 hours, simulating the acidic conditions of food and beverages.

- This procedure follows ASTM C738 standards, as outlined in the FDA’s Compliance Policy Guide CPG 5454.5.

- Lab analysis of the solution then determines the amount of lead released.

You can’t always trust the at home lead testing kits: Learn more here!

FDA Regulations: Keeping You Safe

It’s essential to acknowledge that everything we interact with has some chemical impact. The key is understanding what levels are genuinely harmful. This is where the FDA’s regulations and proper testing play a crucial role.

The FDA has established strict limits on lead leaching in dinnerware:

- Flatware (plates, bowls): 3 milligrams per liter (mg/L).

- Holloware (Bowls): Slightly lower limits than flatware.

- Cups, mugs, pitchers: 0.5 mg/L.

Why the Difference in Limits?

The varying limits reflect the duration of contact between food/drinks and the ceramic surface. Acidic beverages, like orange juice, can further increase lead leaching. Therefore, cups and mugs, which often hold drinks for extended periods, have stricter limits.

Curious about what those glaze labels are even talking about? Read our article: Demystifying Ceramic Glaze Labels

Lead Glazes: Not Inherently Bad, But Require Prudent Handling

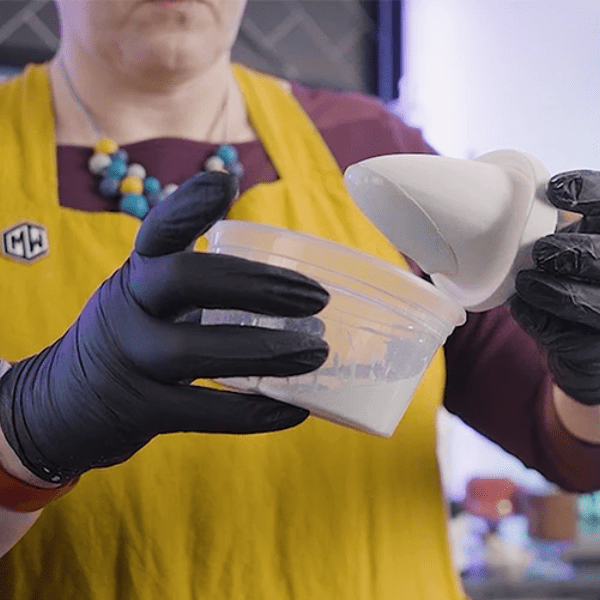

As Matt from Ceramic Materials Workshop emphasizes, “It’s okay to have leaden glazes as long as it’s designed, fired, and tested properly.” This highlights the importance of:

- Proper formulation.

- Accurate firing temperatures.

- Thorough testing.

But… Should I be afraid of lead leaching? Listen to CMW’s podcast For Flux Sake: Episode 61, Should I be afraid of lead leaching?

Knowledge is Power: Your Takeaways

Spreading fear without factual backing is counterproductive. Instead, we should focus on empowering ourselves with knowledge and promoting responsible practices.

- Lead in glazes is not something to be irrationally feared, but it must be treated with respect.

- Modern manufacturing and strict regulations have significantly mitigated lead risks in US-made ceramics.

- Proper testing, especially the 24-hour soak test, is essential for ensuring safety.

- Do not trust at home lead testing kits.

- Always source glaze materials from reputable suppliers.

- Be aware of other heavy metals in glaze, such as cadmium and chromium.

- Understanding the facts empowers you to create and enjoy your pottery safely.

Next Step: Why do pots get hot in the microwave? | For Flux Sake: Episode 82

Ready to dive deeper?

Loved learning about ceramic glazes? Want to go even deeper? Check out our Workshops & Courses, now available in Spanish, or YouTube Channel where Matt breaks it all down, myth-busting and Stull chart included!