“Bloat” in ceramics refers to a specific type of clay defect that happens during the firing process. When clay is fired in a kiln, it undergoes a series of physical and chemical changes.

Bloating is one of the undesirable outcomes that can occur during the firing.

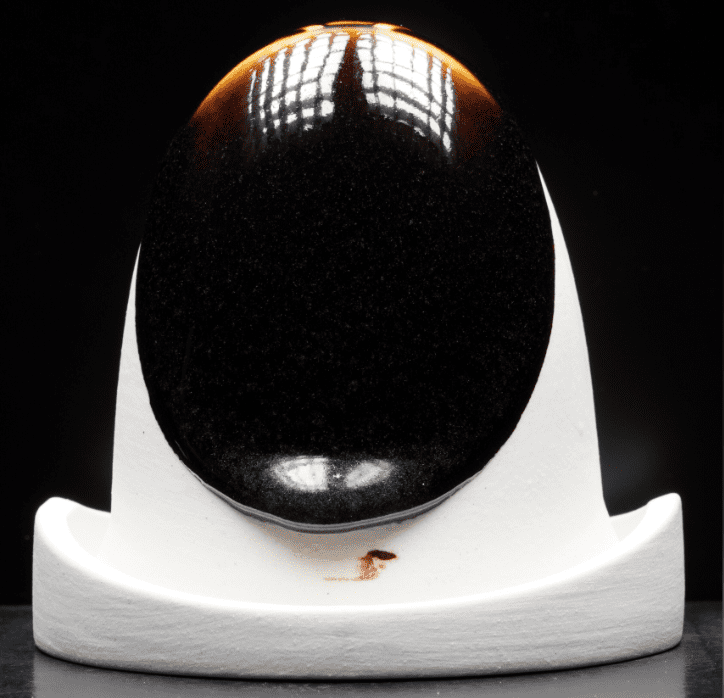

It may appear as small or large bubbles on the surface of the fired ceramic, these bubbles may be open or closed and full of the trapped air. In severe cases, bloating may cause the clay body to warp and bubble. And once you see bloating on a clay, you are far into the problem, as bloating starts microscopically. By the time you can see bloating with the naked eye, the flaw is well established in the clay body.

Although it may be unavoidable at times, there are some ways to prevent it from happening.

Bloat occurs as you fire a clay body, the viscosity of the glass drops and the air in its pores swell and change shape. This swelling causes the clay to expand and form bubbles or blisters on the surface or within the clay structure. Psst… How can I measure my thermal expansion?

Since the viscosity of the glass has reduced, the bubbles are met with less resistance and thus become larger. These bubbles can vary in size and are often accompanied by cracking or other damage to the ceramic object. It happens in all types of clay bodies, but it is seen most often and appears more dramatic in darker clay bodies, as there is decomposing Iron that contributes to the expansion.

Several factors can contribute to clay bloating:

- Clay Composition: The type and composition of the clay itself can influence its susceptibility to bloating. Some clays (especially dark clays) are more prone to bloating than others due to their Iron content. That said all clays will bloat, even porcelains, if over fired

- Firing Temperature: Bloating is more likely to occur at certain temperatures, typically in the middle to high range of the firing process. It is often associated with over-firing. Track your temperatures with cones or a thermocouple.

- Firing Atmosphere: The atmosphere inside the kiln can also affect bloating. Higher Iron containing clays will bloat more in an oxidation firing. Whereas in reduction, the fire utilizes the oxygen, reducing the bloating behavior.

Obviously, bloating is an unwanted ceramic defect because it can compromise the structural integrity and aesthetics of the ceramic pieces. To prevent bloating, potters and ceramic artists often carefully control the firing process, including temperature, firing rate, and kiln atmosphere.

And just remember what Rose always says to do and keep on “Test, Test, Test-Ing”!

Did someone say…FREE?

You can learn how to avoid bloat and even more about your clay bodies in CMW’s Intro to Clay Bodies class. But enjoy a FREE sample lesson on us! Watch CMW’s YouTube below: Sample Lesson | Ceramic Materials Workshop | Introduction to Clay Bodies

Ready to dive deeper?

Loved learning about ceramic glazes? Want to go even deeper? Check out our Workshops & Courses, now available in Spanish, or YouTube Channel where Matt breaks it all down, myth-busting and Stull chart included!