Transform your pottery with the chemistry of glazing! It’s the stage where your creations come alive with vibrant colors, captivating textures, and a protective finish. But achieving those stunning results requires a bit of know-how. Whether you’re a beginner or have some experience under your belt, these five essential glazing tips will set you up for success.

1. Prepare Your Pottery Thoroughly

Think of your pottery like a canvas. You wouldn’t paint a masterpiece on a dirty canvas, would you? The same goes for glazing! Before you even think about dipping that brush, you need to make sure your pottery is squeaky clean.

Why is this so important?

- Glaze Adhesion: Dust, dirt, oil, or even fingerprints can prevent the glaze from properly bonding with your pottery. This can lead to chipping, flaking, and other unsightly blemishes after firing.

- Smooth Surface: A clean surface ensures that the glaze will go on evenly and smoothly, without any bumps or imperfections.

- True Colors: Residue on your pottery can affect the way the glaze fires, resulting in unexpected colors or textures.

How to Clean Your Pottery:

- Bisqueware: If you’re working with bisqueware (pottery that’s been fired once), make sure it’s completely dry before glazing. Any moisture can cause the glaze to crack or flake off during the firing process.

- Cleaning Tools: Use a soft brush, a damp sponge, or even compressed air to gently remove any dust or debris. Avoid using anything abrasive that could scratch the surface of your pottery.

Extra Tip: If you’re handling your pottery a lot before glazing, wear gloves to prevent transferring oils from your hands.

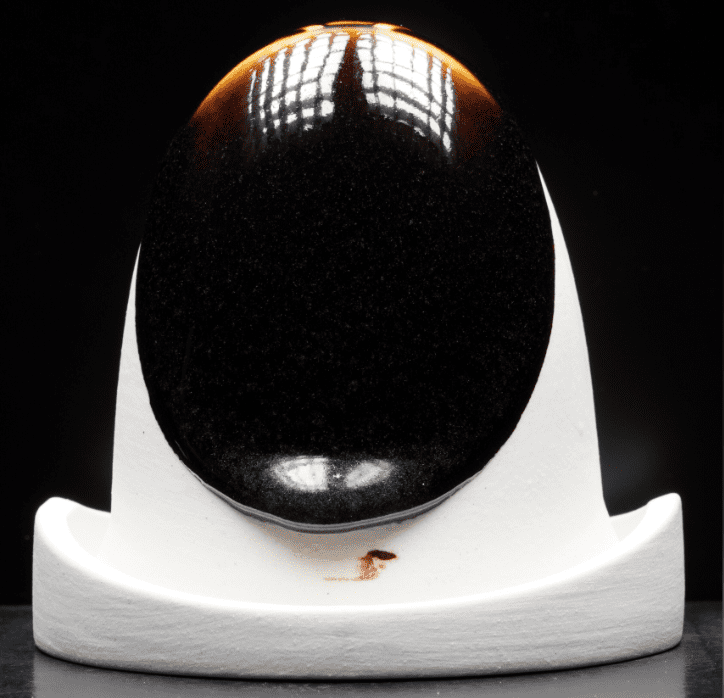

2. Choose the Right Glaze: It’s not Just About Pretty Colors

Okay, let’s be honest, one of the most exciting things about glazing is choosing those gorgeous colors and textures! But before you get carried away with the rainbow of possibilities, there are a few important factors to consider:

I don’t have time for this, why is my glaze so gloopy!?

Clay Compatibility:

- Matching Temperatures: Different clay bodies mature (become durable) at different temperatures. Make sure the glaze you choose is compatible with the firing temperature of your clay. Using a glaze that’s not meant for your clay can lead to all sorts of problems, like cracking, bubbling, or even melting!

- Testing for Success: To ensure compatibility, always test your glaze on a small piece of your clay body before applying it to your finished piece. This way, you’ll know exactly how it will look after firing.

Color and Texture:

- Glossy, Matte, or Textured? Glazes come in a wide range of finishes, from high gloss to velvety matte to rough and textured. Think about the look and feel you want to achieve for your piece.

- Color Palette: Do you want bold, vibrant colors or subtle, earthy tones? Consider how the glaze color will complement the shape and form of your pottery.

Commercial vs. Homemade:

- Ready-to-Go: Commercial glazes are convenient and readily available in a wide variety of colors and textures. They’re a great option for beginners or those who want consistent results.

- Creative Control: Making your own glazes allows you to experiment with unique colors, textures, and effects. It’s also a great way to achieve a specific look that you might not find in commercial glazes.

Pro Tip: If you’re feeling adventurous, try experimenting with different application techniques to create unique effects with your glazes(There’s even a glow in the dark glaze!). Layering, splattering, or even using wax resist can add depth and dimension to your pottery.

Did you know it’s possible to make your own glaze?? Read our blog article “5 reasons you should make your own glazes” to learn more.

3. Apply a Consistent Coat: Brush, Dip, or Spray Your Way To Success

Now for the fun part – applying the glaze! But hold on, there’s more to it than just slathering it on. Whether you’re brushing, dipping, or spraying, the key to a beautiful finish is consistency and control.

Brushing:

- Light Touch: Don’t overload your brush! Think thin coats, not thick globs. Applying multiple thin coats will give you a more even finish and prevent drips and runs.

- Even Strokes: Use smooth, even strokes in one direction to avoid streaks and unevenness.

- Drying Time: Allow each coat to dry completely before applying the next. This will prevent the glaze from becoming too thick and runny.

Dipping:

- Full Immersion: Submerge your piece completely in the glaze bucket to ensure even coverage.

- Timing is Key: To achieve consistent results, time your dips! Start with a 3-second dip and adjust as needed depending on the thickness of your glaze and the absorbency of your bisqueware.

- Clean Removal: When removing your piece from the glaze, do it with a smooth, controlled motion to avoid drips and unevenness.

Spraying:

- Equipment Essentials: Spraying requires specialized equipment like a spray gun and compressor, but it offers excellent control and can create unique effects.

- Particle Size: Adjusting the spray gun settings can give you a variety of particle sizes, from fine mists to heavier droplets, allowing for different textures and finishes.

- Ventilation: Always spray in a well-ventilated area, as glaze particles can be harmful if inhaled.

Glaze Science Alert! Ever wondered why dipping glazes seem to dry almost instantly? It’s all thanks to capillary action! The porous bisqueware acts like a sponge, drawing water from the glaze into the clay body. This leaves the glaze particles on the surface, creating that quick-drying effect.

Some people theorize that our water source affects the glaze. What do you think?

Pro Tip: No matter which application method you choose, always test it out on a test tile first to get a feel for the glaze and how it applies.

Want to learn more about the science behind dipping, brushing, and spraying? Check out our in-depth blog post: “The Science Behind Glaze Application”

4. Glaze Thickness: Finding the Sweet Spot

Think of glaze like Goldilocks and her porridge – you don’t want it too thick, and you don’t want it too thin. You want it just right! Glaze thickness plays a crucial role in the final look of your pottery, so finding that sweet spot is essential.

Need real world examples? Watch our YouTube video: Gravity of the Situation – Specific Gravity and Viscosity in Ceramics

Too Thick:

- Running Glaze: If you apply the glaze too thickly, it can run down your pot during firing, creating uneven coverage and potentially even sticking to the kiln shelf (a potter’s nightmare!).

- Cracking and Flaking: Thick glaze applications are also more prone to cracking or flaking off during firing or cooling.

Too Thin:

- Patchy Coverage: If the glaze is too thin, it might not fully cover the clay body, resulting in bare spots or a washed-out appearance.

- Weak Color: Thin glaze applications can also result in weak or uneven color development.

Finding the “Just Right” Thickness:

- Test Tiles are Your Friends: The best way to find the ideal thickness is to experiment on test tiles. Apply different thicknesses of glaze and fire them alongside your pottery to see how they turn out.

- Visual Clues: As you apply the glaze, look for a smooth, even coating that’s not too runny or too thick. It should be similar to the consistency of heavy cream.

- Glaze Viscosity: The viscosity of your glaze (how easily it flows) also affects the thickness. A thicker glaze will obviously apply thicker. You can use a tool called a Zahn cup to measure and control the viscosity of your glaze for more consistent results.

Pro Tip: The temperature of your bisque firing can also affect glaze thickness. A higher bisque temperature will result in a more porous clay body, which will absorb more glaze and result in a thicker application.

But wait… my kiln is too old and not super reliable! Read our blog, Ceramic Kiln Maintenance and Testing: Why Is It Important?

5. Fire the Pottery Carefully

The kiln is where the real magic happens! It’s where your carefully glazed pottery transforms into a finished piece, with vibrant colors and a durable surface. But firing can also be a source of frustration if you’re not careful.

In our podcast, For Flux Sake, Episode 91, we address how to get the best firing out of your new kiln!

Kiln Know-How:

- Firing Schedules: Every glaze has a recommended firing temperature and schedule. Follow these guidelines carefully to achieve the desired results. Even a slight variation in temperature can drastically affect the color, texture, and overall appearance of your glaze.

- Cone-sider this: “Cones” are small pyramids that melt at specific temperatures, indicating when your pottery is done firing. Understanding cone charts and using the correct cone for your glaze is essential for successful firing. (Wait… I don’t understand!)

- Kiln Quirks: Get to know your kiln! Every kiln has its own personality, with potential hot spots and temperature variations. Understanding these nuances will help you achieve even firing and avoid unexpected results. (The Heat is On! A Beginners Guide to Glazing & Firing Pottery!)

Can I create atmospheric effects in an electric kiln?? This is addressed in CMW Podcast For Flux Sake Episode 53

Safety First:

- Kilns Get HOT: Remember, kilns get extremely hot! Always prioritize safety by wearing appropriate protective gear, like heat-resistant gloves and eye protection.

- Ventilation: Make sure your kiln room is well-ventilated to prevent the buildup of harmful fumes.

- Never Leave Unattended: Never leave a kiln unattended during firing. Unexpected problems can arise, and it’s important to be there to address them.

Beyond the 5 Tips: Embrace the Experiment!

By following these five essential glazing tips, you’ll be well on your way to creating beautiful, high-quality pottery. But don’t stop there! The world of ceramics is full of exciting possibilities. Experiment with different glazes, techniques, and firing schedules to discover your own unique style.

Remember:

- Practice Makes Progress: Don’t be afraid to make mistakes. Every mishap is a learning opportunity in disguise. (Click me if you’re scared of mistakes!)

- Test, Test, Test: Always test your glazes and techniques on small test tiles before committing to your final pieces. (Buy molds for test tiles here!)

- Keep a Pottery Journal: Document your clay type, glaze recipes, firing temperatures, and any observations you make along the way. This will help you track your progress and learn from your experiences.

And most importantly, have fun! Glazing is a journey of discovery and creativity. Embrace the process, and enjoy the satisfaction of transforming your clay creations into works of art.

Ready to dive deeper?

Loved learning about ceramic glazes? Want to go even deeper? Check out our Workshops & Courses, now available in Spanish, or YouTube Channel where Matt breaks it all down, myth-busting and Stull chart included!